Laser Cutter Chiller

- High-Efficiency Cooling Solutions

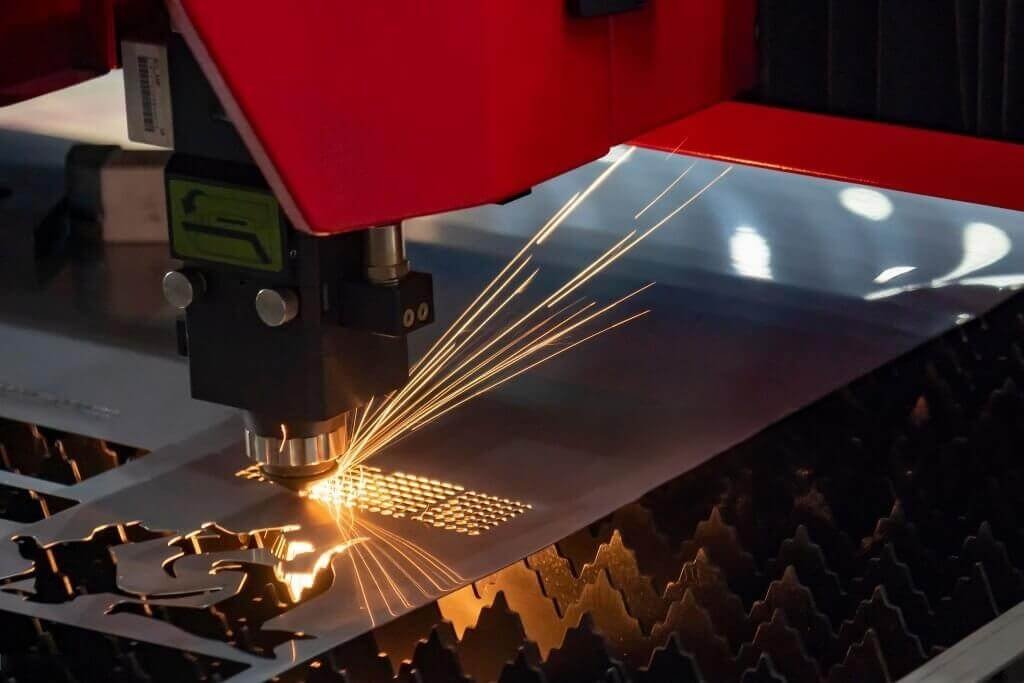

What Are the Main Types of Laser Cutting Machines on the Market?

- CO2 Laser Cutters: These work best for non-metals like wood, acrylic, and plastic, plus thin metals. They use a 10.6μm wavelength.

- Fiber Laser Cutters: Great for cutting metals such as stainless steel or aluminum, they deliver high efficiency at 1.064μm.

- YAG Laser Cutters: Once used for small metal jobs, this older tech has mostly been replaced by fiber lasers.

- UV Laser Cutters: Perfect for precision work, like electronics, they operate at a 355nm wavelength.

In short, each type affects your laser cutter water chiller’s cooling needs. Want more details? See this guide by Laser Focus World.

What's the Leading Brands for Laser Cutting Machines?

Below are the top brands in the laser cutting market, categorized by their product types, models, power ranges, and mainstream applications:

Trumpf

- Types: Fiber and CO2 laser cutters.

- Models & Power:

- TruLaser 3030 (Fiber): 2kW-20kW.

- TruLaser 5030 (CO2): 3kW-12kW.

- Mainstream Applications: High-precision metal cutting (fiber) and versatile non-metal/metal processing (CO2), widely used in automotive, aerospace, and sheet metal industries. Visit Trumpf’s product page for details.

Bystronic

- Types: Fiber laser cutters.

- Models & Power:

- ByStar Fiber: 2kW-15kW.

- Mainstream Applications: Efficient metal cutting for medium to thick plates, targeting manufacturing and metal fabrication sectors. Explore more at Bystronic’s official site.

Han’s Laser

- Types: Fiber laser cutters.

- Models & Power:

- HFL-3015: 1kW-30kW.

- Mainstream Applications: Industrial-scale metal cutting, popular in machinery, construction, and heavy industry due to its wide power range. See Han’s Laser website for more info.

Penta Laser

- Types: Fiber laser cutters.

- Models & Power:

- BOLT Series: 3kW-60kW.

- Mainstream Applications: High-power cutting of thick metals, aimed at heavy industrial applications like shipbuilding and structural steel processing. Check Penta Laser’s solutions for specifics.

These machines require tailored laser cutting water chillers based on their power and type to ensure optimal performance.

What Are the Applications and Power Ranges of These Laser Cutting Machines?

The power of a laser cutter determines its application. Below is a table of typical uses and power distribution:

| Power Range | Applications | Material Thickness |

|---|---|---|

| 1kW-3kW | Thin sheet cutting (e.g., signs) | <10mm carbon steel, <5mm SS |

| 4kW-12kW | Medium-thick plates (e.g., parts) | 10-20mm carbon steel, 5-15mm SS |

| 15kW-60kW | Thick plates (e.g., heavy industry) | >20mm carbon steel, >15mm SS |

Higher power requires an industry-grade chiller with greater cooling capacity. For more on laser power applications, see this article by The Fabricator.

How Do You Calculate the Cooling Capacity for a Matching Laser Cutter Water Chiller?

To select the right air-cooled water chiller:

- Step 1: Identify laser power (e.g., 5kW).

- Step 2: Calculate heat output (5kW × 65% = 3.25kW for fiber lasers; UV lasers may vary).

- Step 3: Add 20%-30% buffer (3.25kW × 1.25 = 4.06kW, recommend 5kW chiller).

- Tips: CO2 lasers need tighter temperature control (15-22°C), fiber lasers require higher flow, and UV lasers demand precise cooling for micro-processing. Learn more about chiller sizing at Chiller Systems Guide by Process Cooling.

Which Laser Cutting Machine Models Match Our Laser Chillers?

Below is an analysis of mainstream laser cutting machine models from top brands, including their power, heat output, required cooling capacity, and recommended APT air-cooled water chiller models:

| Brand | Người mẫu | Kiểu | Power (kW) | Heat Output (kW) | Required Cooling (kW) | Recommended Cooling (kW) | APT Model | APT Cooling Capacity (W) | APT Flow (L/min) |

|---|---|---|---|---|---|---|---|---|---|

| Trumpf | TruLaser 3030 | Fiber | 6 | 3.9 (65%) | 3.9 | 4.9 | APTBL-5FCS | 5000 | 14.4 |

| Trumpf | TruLaser 5030 | CO2 | 6 | 4.8 (80%) | 4.8 | 6.0 | APTBL-8FCD | 8000 | 58 |

| Bystronic | ByStar Fiber | Fiber | 10 | 6.5 (65%) | 6,5 | 8.1 | APTBL-10FCD | 10000 | 72 |

| Han’s Laser | HFL-3015 | Fiber | 12 | 7.8 (65%) | 7.8 | 9.8 | APTBL-12FCD | 12000 | 86 |

| Penta Laser | BOLT Series | Fiber | 20 | 13.0 (65%) | 13.0 | 16.3 | APTBL-20FCD | 20000 | 143 |

Notes: Heat output is estimated (fiber: 65% inefficiency, CO2: 80% inefficiency). Recommended cooling includes a 25% buffer. APT models are selected based on the closest higher cooling capacity and sufficient flow rate.

Why Choose our water chiller?

- Efficient Cooling: Supports laser cutters from 1kW to 60kW with rapid heat dissipation.

- Precise Temperature Control: ±0.5°C accuracy for stable laser performance.

- High Flow Design: Up to 40L/min to meet high-power laser cutting demands.

- Smart Monitoring: Real-time water temperature and flow display with auto-alarm.

- Energy-Saving: Air-cooled water chiller design reduces operational costs.

Quick Calculator for Laser Cutter Chiller

Laser Chiller Calculator

Enter your laser power and type to find the right APT air-cooled chiller.

Results:

Electro-Optical Efficiency:

Total Heat Output: kW

Required Cooling Capacity: kW

Recommended Cooling Capacity (with 25% buffer): kW

Recommended APT Model:

APT Cooling Capacity: W

APT Chilled Water Flow: L/phút